UV Curable Coatings

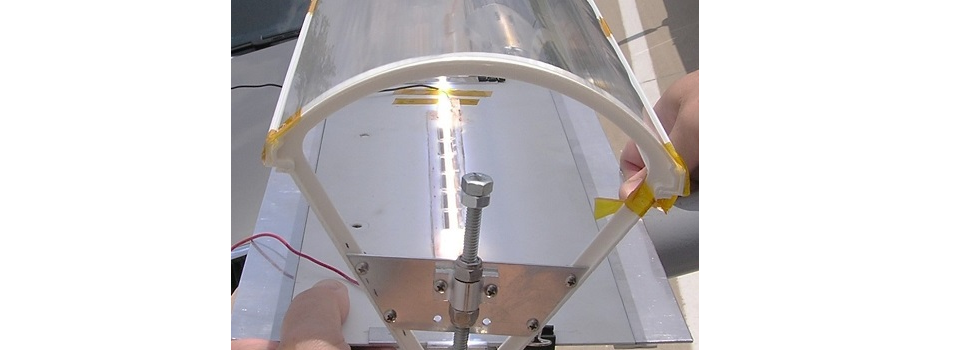

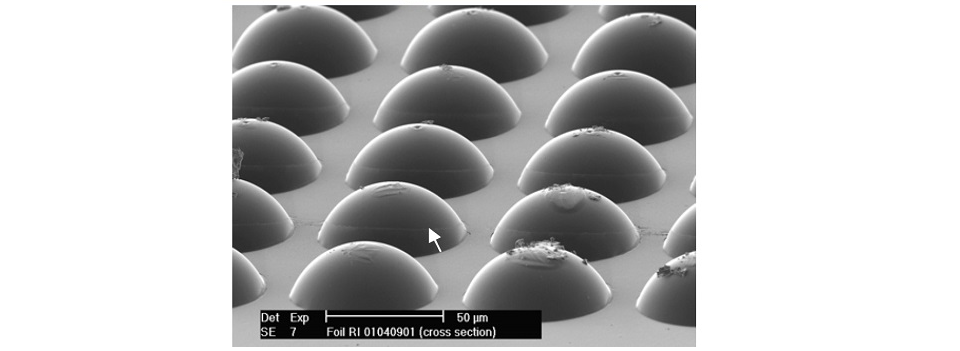

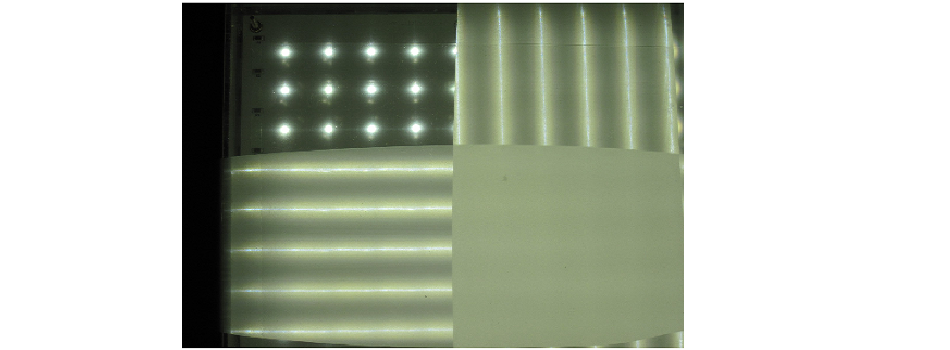

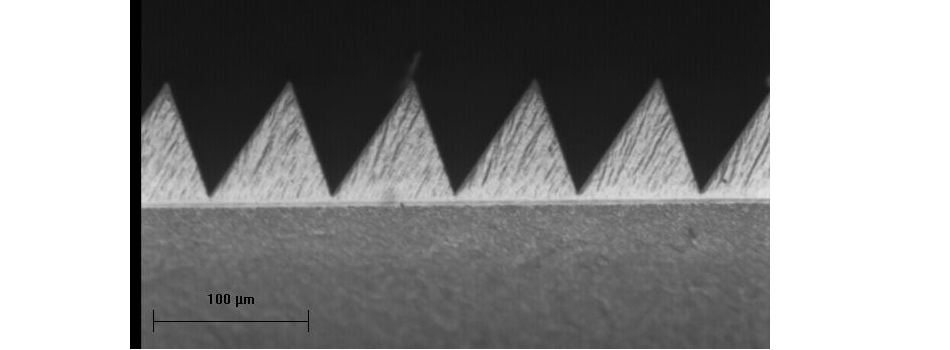

At the heart of our business are the UV curable resins that we develop. These resins, or lacquers, are coated onto a clear base film which is then cured hard by ultraviolet light to create the micro‑embossed structures which refract light. The resins provide high fidelity replication of the master mould and have been used to replicate anything from diffraction gratings of 200nm pitch to optical structures of 250+µm in height.

We formulate the resins in-house and they are manufactured to our exacting specification. Whilst we have a range of general purpose resins, we also develop new formulae for particular applications.

Our coatings are acrylate based and are designed to work on a variety of substrates, the most common being:

|

Type |

Example materials and suppliers |

|

polyethylene terephthalate (PET) |

Melinex or Mylar from DuPont Teijin |

|

polycarbonate (PC) |

Lexan from Sabic |

|

acrylic (PMMA) |

Plexiglas from Evonik |

We have also carried out UV embossing on substrates such as cellulose-triacetate (TAC), biaxially orientated polypropylene (BOPP), and polyurethane (APU and TPU) films.

Our resins can be modified to provide a range of characteristics such as:

- good adhesion to the base film

- longterm UV stability

- good release from a film

- different viscosities

- high hardness

- low shrinkage

- Refractive indices between 1.4 and 1.6

- flexibility

- food safe versions

- pigmented

- NIR transmission

- diffusive containing micro-beads or particles

- suitable for cast and cure applications

In addition to these conventional applications, we have supplied resins for:

- optically clear adhesive layers

- high gloss coatings for ceramics

- resins for stereo-lithography (SLA)

- jewellery making (similar to UltraDome or Magic-Glos from Lisa Pavelka)

Contact us if you wish to discuss new applications or have an enquiry.