Lighting

Introduction

LED's are becoming increasingly common in lighting unit design as they offer high efficiency, reliability and extended product lifetime. However because they are high brightness, point light sources they present a number of optical challenges to lighting designers including control of glare and beam angle, and producing large area units with homogenous light output.

Film Optics has extensive experience of developing solutions for optical challenges gained in a number of complimentary fields including display unit and back light unit design. We can provide consultancy and optical design input into the process of new luminaire design. We can also develop bespoke optical structures to meet specific customer needs that can provide you with a clear advantage in an increasingly competitive marketplace.

We offer a number of optical structures all of which can be produced and supplied on a variety of film substrates (typically PET, PMMA or PC) or laminated onto rigid, flat sheets.

Functional Films

High Efficiency Diffusers - new

|

|

Standard opal diffusers contain particles bound within the body of the film to create a semi-opaque product. These particles diffuse the light passing through a film, but in doing so, they greatly reduce its efficiency, often achieving light transmission of only 50%.

Our diffusers are made on a clear base film which is then patterned to create random microstructures on the film surface. These structures are made of a clear acrylic resin which defract the light as it passes through the film, creating an effective diffuser but without any light loss, resulting in a transmission value of 91%.

A single side coated film has a FWHM of 20° (±10° from the normal), whereas by coating both sides of the film a FWHM of 30° (±15° from the normal) can be achieved. Films can also be laminated onto a thicker base sheet to create a rigid diffuser - perfect for including into a lighting fixture.

The diffusers can be made on the substrate of your choosing; typically PET, PC or PMMA.

Developmental samples are currently available for testing purposes. Contact us for details or samples.

Datasheets for 1-sided and 2-sided films.

|

|

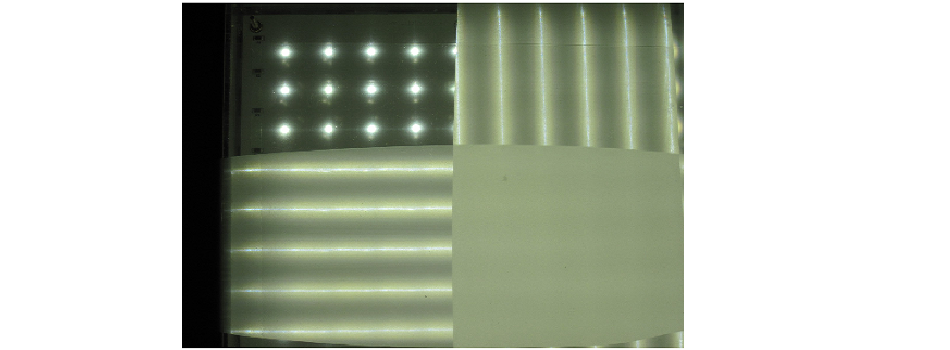

Lenticular Diffusers

|

|

Used to homogenise LED strip lights and remove ‘hot spots’. We can provide lenticular diffusing film in continuous reels and cut to the width of your luminaire. This film is also particularly well suited for use in machine vision applications where a uniform strip of light is required

|

|

|

Light Control Film

|

|

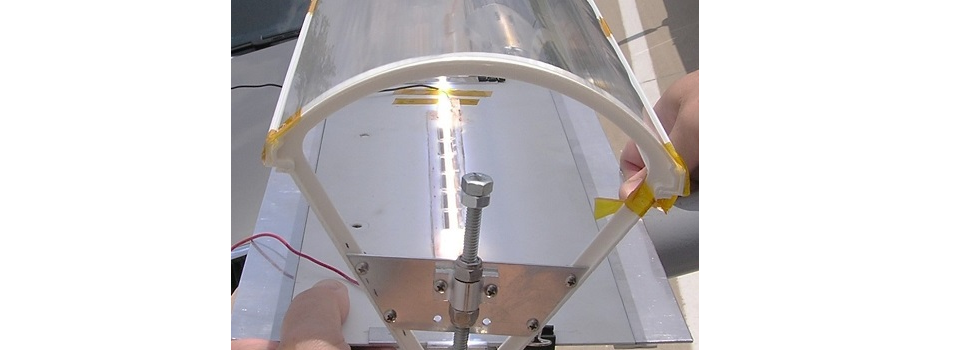

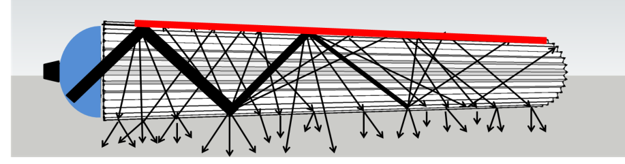

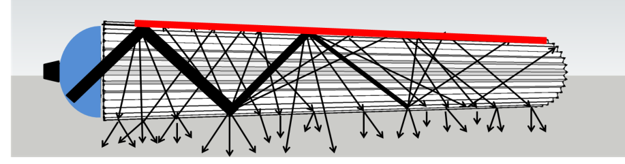

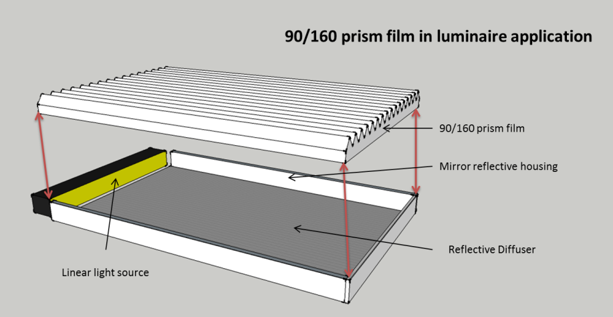

This film has the unique characteristic of being either reflective or transmissive depending on the angle that lights hits the film. It is typically used to produce homogenised light output along a linear luminaire. This film is similar in function to Optical Lighting Film 2405 from 3M®.

|

|

|

Light Control Film used with reflective diffuser to produce a large downlight.

|

|

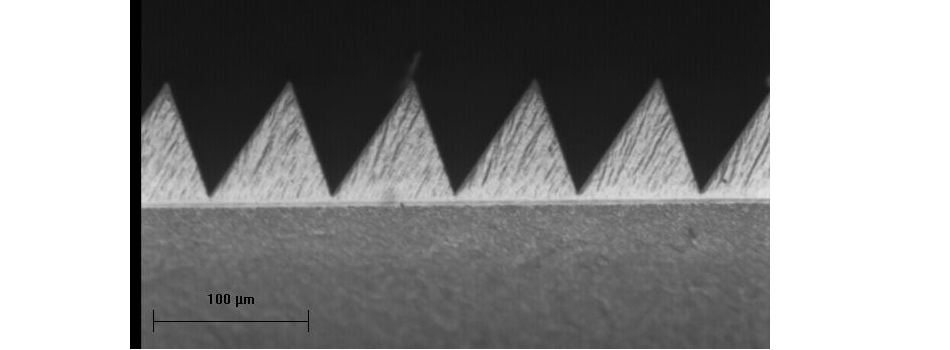

Light Turning Film

|

|

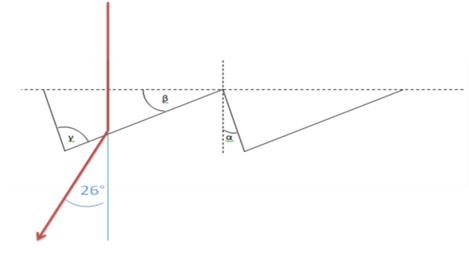

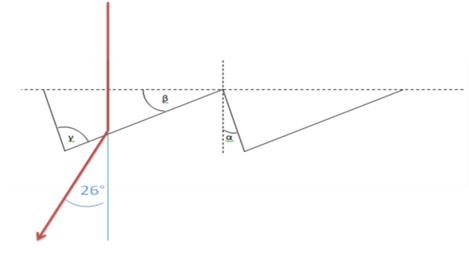

Used to alter output beam angle in one direction. Typically the maximum angle that light can be turned through is 26°, although 29° is possible using higher refractive index resins. Tooling can also be made to turn light through smaller angles.

The turning angle can also be varied according to position - similar to a linear Fresnel lens - to either focus light to a line, collimate it, or disperse it.

|

|

Batwing Diffuser Film

|

|

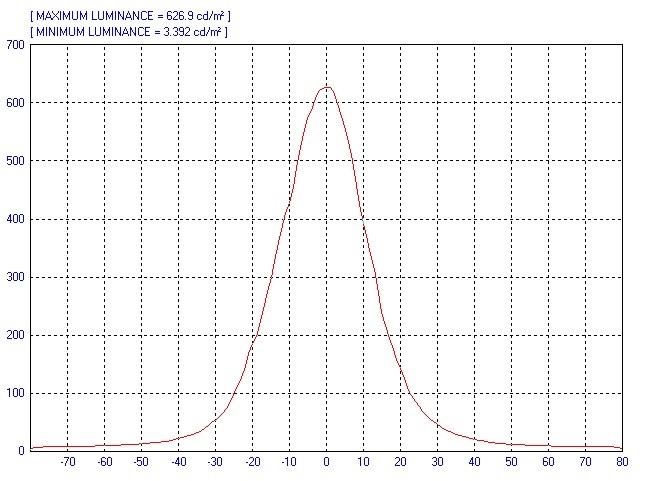

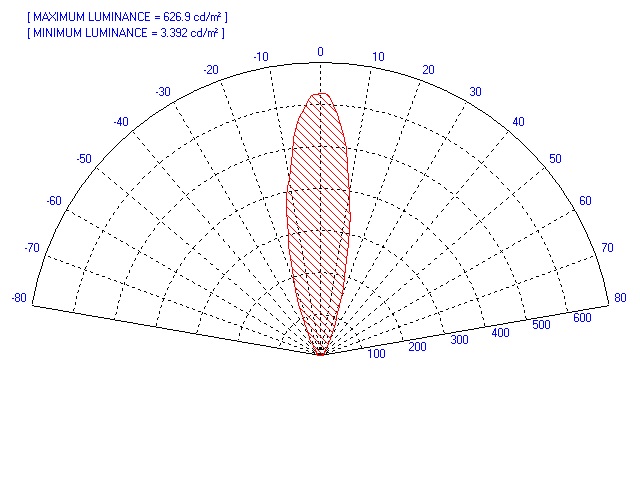

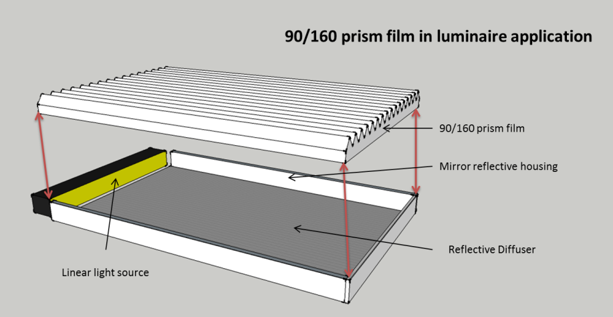

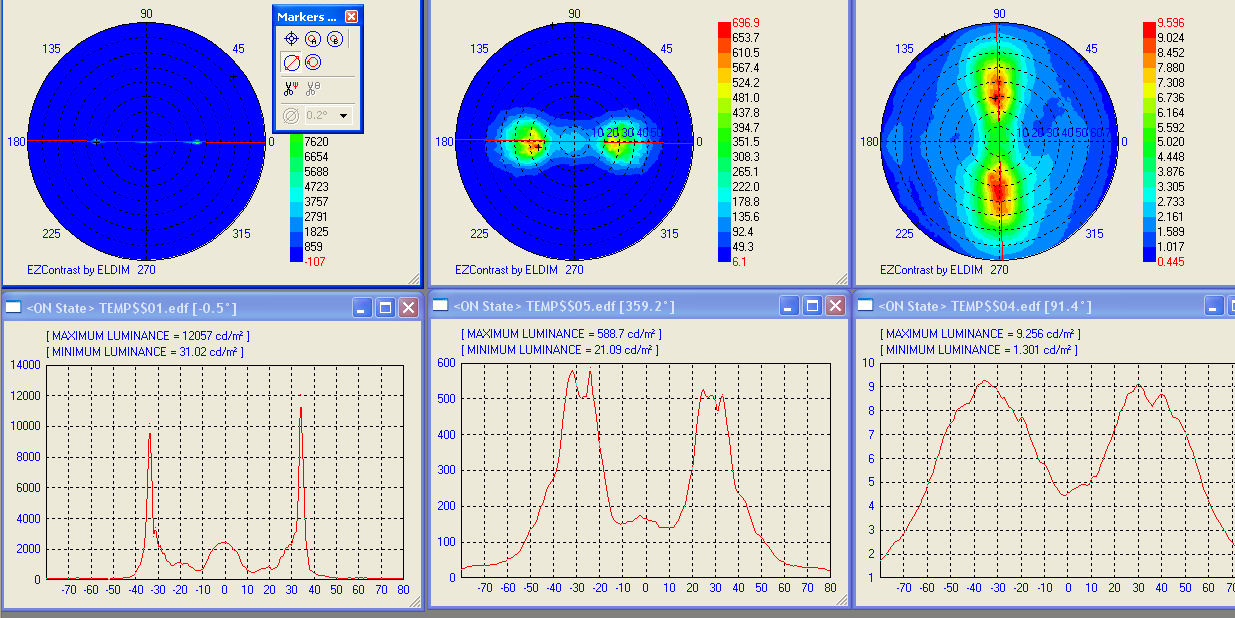

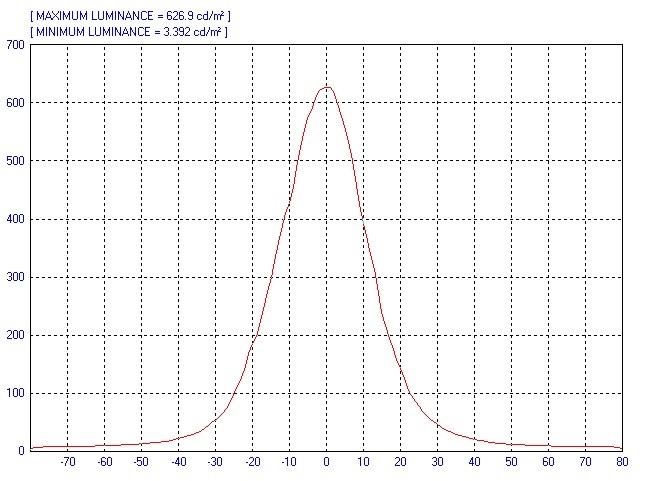

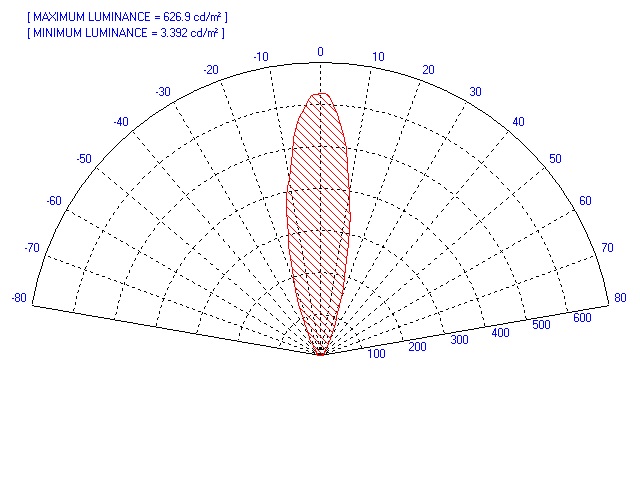

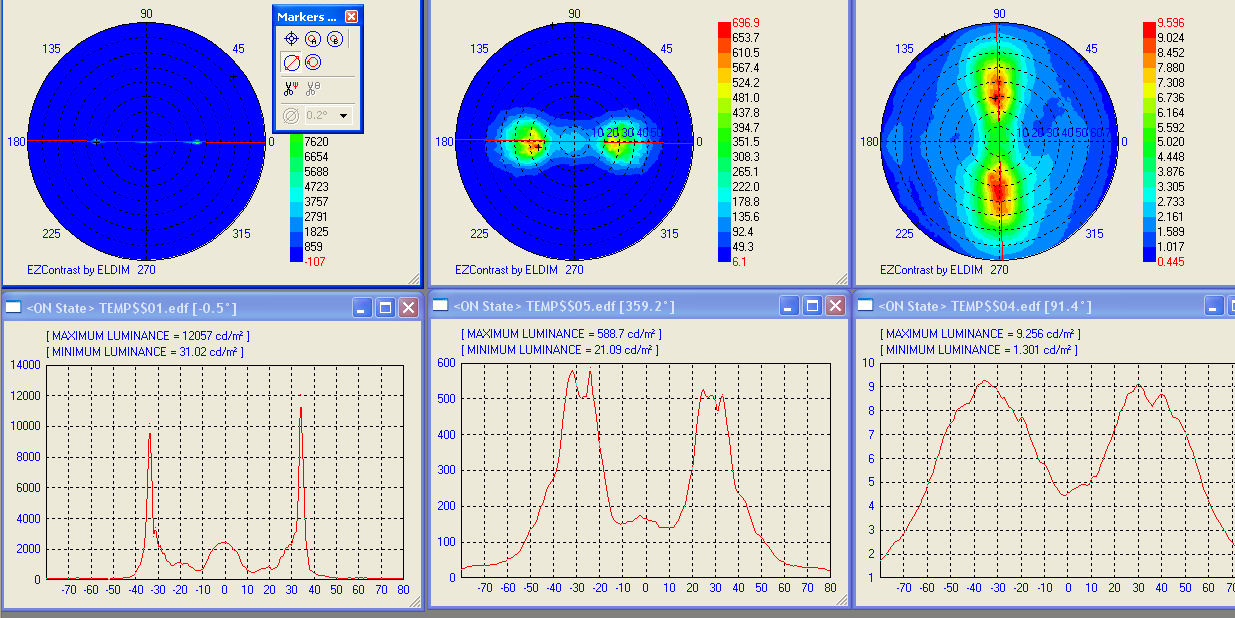

Many of our films can be combined in order to to create a variety of functions, such as a Batwing Diffuser made by combining our SPF90/160 film with a diffuser.

|

|

Light Deflecting Film

|

|

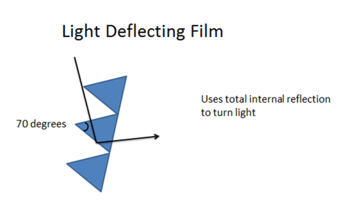

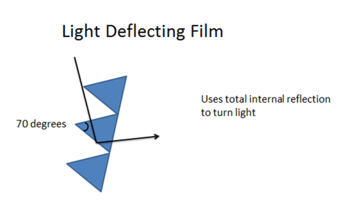

Uses Total Internal Reflection (TIR) to deflect light through 90 degrees.

|

|

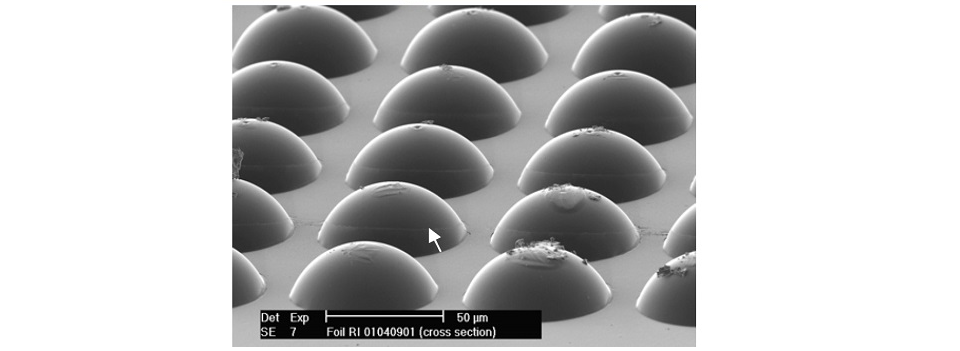

Micro-lens Arrays

|

|

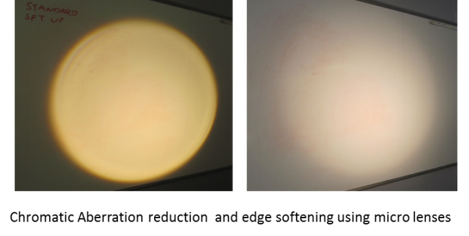

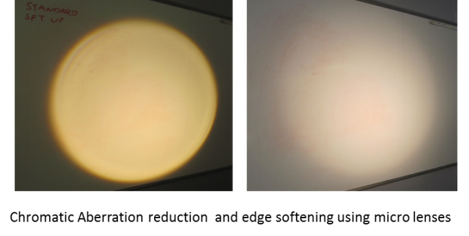

Used to remove the effects of chromatic aberration and soften beam edges. Can also be used as a diffuser.

|

|

Decorative or Artistic Applications

Many of our films can also be used to create stunning visual effects – either singularly or in combination. Have a look in the Gallery below for some ideas.

|